Paxton Products designs and manufactures high performance air delivery systems that are custom engineered to optimize drying, blow off and cleaning of your products. The process begins with your application: what size, what shape, what speed, how much water or debris to be blown, what configurations—then the air delivery device is engineered to these requirements. No matter what configuration of air is needed, Paxton has it, from drying a single surface to 360 degree drying.

Select Air Delivery Device of interest:

CanDryer CapDryer Centrifugal Blowers Inline Manifolds Mass Drying Nozzle Manifolds PowerDry Single File Drying Spyder Manifolds Top & Side Inlet Air Knives

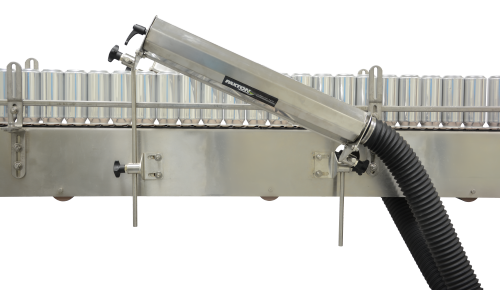

CANDRYER

Paxton's CanDryer replaces conventional air knives and nozzles with all-in one manifold to improve drying while enhancing usability and product floor safety. The CanDryer provides complete drying of 8 oz and 24 oz cans to improve quality of coding, labeling and packaging.

Features:

-

-

-

-

-

-

- Thoroughly dries the tops and sides of 8 oz - 24 oz cans

- Eliminates variability due to air knife positioning

- Improve safety by restricting water spray

- Easily adjustable for varying can heights

-

-

-

-

-

Click here to learn more about our CanDryer System.

CAPDRYER

The Paxton CapDryer provides complete drying of the bottle neck and lid to improve quality of coding, tamper banding, labeling and vision system results. It is available in 2 sizes, to fit most bottle types & conveyor configurations. The CapDryer systems target the neck and lid of most bottle types and sizes, and when coupled with a Paxton PX-series blower, thoroughly dries the cap and throat within an 18-30” footprint.

Features:

-

-

-

-

-

-

-

- Reduce false readings from vision systems

- Improved adhesion and positioning of label and tamper band

- Eliminate coding quality issues due to smearing

- Easily adjustable for varying bottle sizes

-

-

-

-

-

-

Click here to learn more about our CapDryer System.

CENTRIFUGAL BLOWERS

Paxton Centrifugal Blowers offer ultra-high efficiency solutions for process air, drying, vacuum and air rinsing applications. Paxton’s new PX-series blowers provide a step-change in blower efficiency, with the PX-series blowers as much as 30% more efficient than the previous generation blower. The PX-series blowers are available in sizes from 3 hp to 20 hp, with air flows from 100 cfm to 1500 cfm.

Features:

-

-

-

-

-

-

-

- More Power

- Less Energy

- More Efficient

- Highly Reliable

-

-

-

-

-

-

All of our Air Delivery Devices systems are powered by our high-efficient PX-series Blower. Click here to learn more about our Centrifugal Blower.

INLINE MANIFOLDS

The Inline Manifold is ideal for drying the tops or bottoms of cans, jars, and other containers thoroughly, prior to date coding or other packaging operations. The Inline manifold has six nozzles focused on the top surface of the product and is available with either a polypropylene manifold or a 304 stainless steel manifold, both with Loc-Line nozzles. Click here to learn more about our inline manifolds.

MASS DRYING

Our Mass Drying solution is comprehensive for drying containers and other packaged goods prior to inspection systems, coding, labeling, and secondary packaging. Our solution optimizes packaging lines by effectively drying containers without the need to divert to single-file. Click here to learn more about our mass drying solution.

NOZZLE MANIFOLDS

Paxton Nozzle Manifolds are ideal for applications exhibiting a larger distance between the air source and the surface to be dried or blown off. Nozzle Manifolds maintain thrust as far away as 18 inches. Click here to learn more about our nozzle manifolds.

POWERDRY

The patented PowerDry System replaces costly compressed air blow offs for date coding and other bottling and canning operations. The PowerDry System by Paxton Products lowers energy costs by as much as 80% through reduced compressed air usage in bottling, canning and other packaging operations.

Features:

-

-

-

-

-

-

-

- Pays for itself in energy savings in about a year

- Removes debris and moisture effectively with high velocity air flows

- Eliminates contamination from oils and scale by eliminating compressed air

-

-

-

-

-

-

Click here to learn more about our PowerDry System.

SPYDER MANIFOLDS

The Spyder Manifold is the most effective system for drying tips, sides and under the rim of cans, bottles and jars, as well as spot drying for hard to reach areas of industrial products or areas needing extra attention, such as holes. Spyder Manifolds combine inline nozzles with 'spider-like' arms that flex to any position to reach under and around to accommodate specific drying needs. The spyder arms quickly adjust to different sizes and shapes, for multi-purpose lines. Click here to learn more about our spyder manifolds.

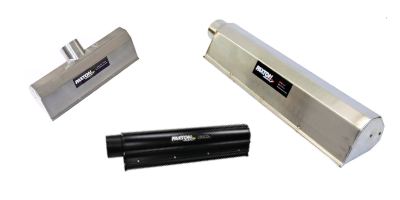

Top & Side Inlet Air Knives

Paxton Air Knives are designed to give maximum efficiency for high velocity drying, blow off, and air rinsing applications. The air knives feature a continuous, uninterrupted air slot design that gives uniform coverage over the target area, with a standard gap setting of 0.055 inches. Click here to learn more about our air knives.

Interested in one of our solutions?

Click the button to fill out a RFQ, Email us at sales@paxtonproducts.com, or Call our application engineers at 513-982-6099.

HISTORY

For over 60 years, Paxton has led the industry in innovation and design of centrifugal blowers for blow-off and drying systems for the manufacturing industry. Paxton Products has its roots in the development of the first high-performance supercharger in 1957. This same technology was used to create the first centrifugal blowers for industrial applications in the 1970s. Paxton Products not only offers superior products but also provides unrivaled engineering expertise and an industry-best warranty of 3 years compared to their competitors’ 1-year warranty. Within the 60 years plus of operation, Paxton has gained industry expertise to make us the preferred solution for drying and blow-off applications around the world.